The LEAN production or one -piece flow of Epsilon has permitted the implementation of more than 66 lines of production each composed of an autonomous team of 20 workers in average. Each line of production produces one type of product.

The LEAN principle is to minimize the number of Work-in-progress (WIP) in order to obtain a short lead time.

The multi-functionality of our production lines, a real challenge for the company, responds to the reactivity expected by our clients while keeping an outstanding quality level. This multi-functionality associated with LEAN assures the quality and the respect of production deadlines.

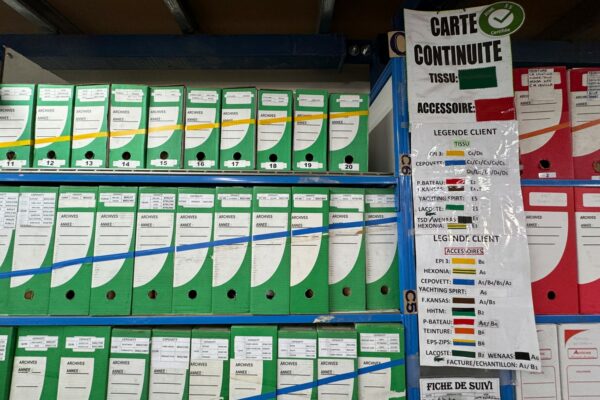

Lean management at Epsilon is also present throughout the value chain. From receipt of materials through to dispatch, the teams use tools and methods such as 5S and visual management on a daily basis to optimise all processes. In this way, all Epsilon's teams are focused on serving our end customers under the best possible conditions in terms of cost, quality and delivery times.